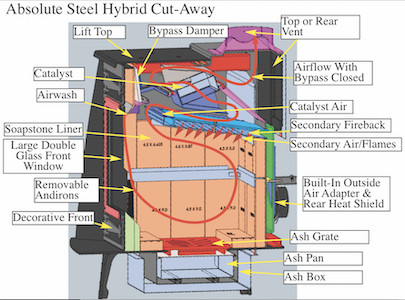

Our hybrid stoves combine catalytic combustion and secondary combustion to reduce emissions as much as possible, and to improve efficiency. Until recently, wood stoves used either a catalytic combustor or a secondary combustion system to meet EPA emissions standards. In 2011 Woodstock Soapstone Company combined both systems, and introduced the first hybrid stove in America: The Progress Hybrid Woodstove.

Each system (catalytic combustion and secondary combustion) was capable of meeting the EPA emissions standard by itself, so why go to the trouble and expense of developing a wood stove that combines these two separate systems? The answer lies in the way each system performs best. A catalytic combustor has the ability to dramatically reduce woodstove emissions at temperatures as low as 300 degrees F. This allows clean combustion at very low burn rates, and the catalytic combustor produces a considerable amount of heat from the wood smoke, which boosts efficiency.

The secondary combustion system requires much higher temperatures to ignite (over 1000 degrees F) and break down the same compounds in the wood smoke. Secondary combustion works best at medium and high burn rates, and it reduces the workload on the catalyst as the burn rate and heat output go up.

Combining these two different systems in one wood stove makes the stove clean and efficienct through a wide range of outputs. Seems simple, right?

Ten years later, we are still working to improve both systems. We now make the basic metal “substrate” or uncoated metal catalyst to better control cost and quality. We build our catalysts with a high-tech stainless steel foil, developed in Germany. The foil is only 50 microns thick (the thickness of a human hair) so it heats up and “lights off” very quickly. Its chemical components make it suitable for continuous operation at 2100 degrees F – higher temperatures than generated inside of a wood stove.

We have redesigned all of our air intakes for the new 2020 EPA standards, and all of our damper systems are designed so that all air intakes (primary, secondary, and catalyst air) are controlled using a single, simple lever. The ratio of primary to secondary air is pre-set so the user does not have to fiddle with separate knobs or levers to “fine tune” emissions or output.