|

| Condition of Palladian in need of refurbishment |

We have restored many stoves for customers who lost their homes, and most of their possesions, to floods, hurricanes, earthquakes, and fires. Sometimes the only thing left standing after these disasters was our customer’s Woodstock Soapstone stove. Many of these stoves make their way back to our factory to be restored. For our customers, the stove may be the only surviving item from their “pre-disaster” life.

Our stove builders have yet to encounter a stove that could not be fully refurbished. In the next couple of pages, we’ll highlight some of the refurbishment stages that the 15 year old Palladian (pictured above) went through to get it back in “Like New” condition. This stove survived a house fire (not related to the stove) and then sat in a barn for three years. It arrived with lots of rust, and not in usable condition.

The first step in the restoration process is the initial assessment to determine what parts need replacing, how much labor will be involved, and what the customer’s expectations are.

In the case of this Palladian Wood Stove, the stove needed to be completely torn down in order to address the severity of rust on both the interior and exterior parts. With approval from the customer, the tear down/restoration began.

The biggest surprise came when the top lid was removed. Out sprung a mouse that quickly scurried away! The removal of the top disturbed the cozy home the mouse made in the upper combustion chamber (shown below).

|

| Mouse nest found under the top lid |

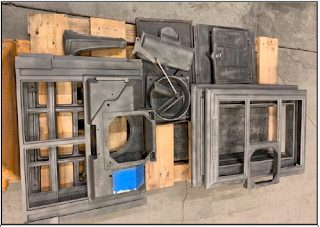

With the occupant evicted, the mouse nest was removed and the stove fully disassembled. All of the reusable soapstone slabs were set aside on a pallet to be sanded, and all the cast iron components were sandblasted and then painted. The internal components were painted black, and the exterior castings for this stove were painted Metallic Gray (the original color).

|

| Castings before sandblasting |

|

| Castings after sandblasting |

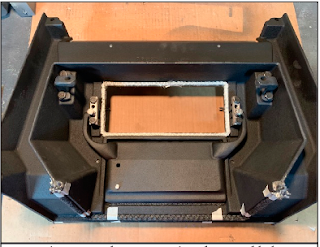

With the stone sanded and the cast iron looking like new, the replacement parts were gathered and the process of rebuilding the once rusty stove got underway (see image below).

The cast iron frame and soapstone panels were assembled onto the base, with the pieces fitting together like a three dimensional jigsaw puzzle. After all the pieces were assembled, the stove builder began cementing and sealing the internal seams.

The cement sealant and new gaskets were installed to make the stove a “controlled combustion” stove, meaning the combustion air can only come in through the designated air inlet at the rear of the stove.

With the stove body complete, the upper combustion chamber (called the “combustor pan”) was sub-assembled.

|

| A new combustor pan is sub-assembled before installing |

The combustor pan was then installed into the top stove cavity, and the catalytic combustor fitted to it. Finally, the rebuilt stove top was placed onto the stove and the final touch-ups were completed.

|

| The new combustor pan installed in the stove |

The damaged Palladian Wood Stove is now fully refurbished (see below) in “Like New”condition, and ready to provide many, many years of enjoyment and radiant soapstone warmth.

|

| Fully restored Palladian |

Summer is a good time to have your stove serviced. It’s before our busy fall shipping season, and we can normally make quick turn-arounds on restoration work. To schedule service work, call us at 1-800-866-4344.