30 Nov

We have shared “beta” aesthetic designs for our new hybrid, and we also plan to share “beta” test results for those who are interested. This is the first of what will be several posts about beta emissions/efficiency testing for our new (and still nameless) Model 211 Hybrid, which is scheduled for EPA emissions testing in January, 2016.

EPA is planning to gradually transition from testing with Douglas Fir “cribs” to testing with cordwood, in order to generate test results that are closer to “real world” results.

Part of the change to cordwood testing contemplates “cold start” testing. This would help to define emissions produced at start-up, when a fire is initially kindled.

The industry has produced a “cold start protocol” which we used to generate the results below. We’ll have a lot to say about the protocols suggested by the industry for cordwood testing in the near future. Admittedly, the proposals put forth by industry are very much a “work in progress” to put it kindly.

Anyway, the focus on cold starts is probably a good thing, since we can learn how to start stoves cleanly, with low emissions.

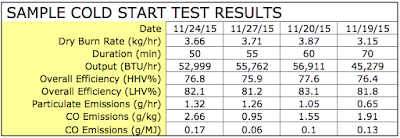

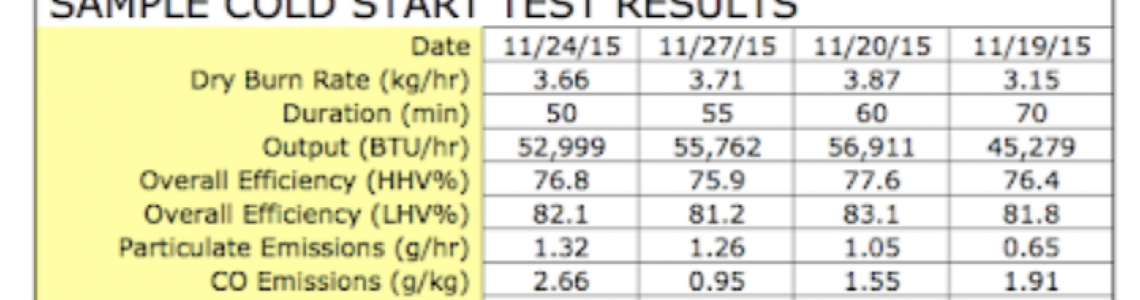

We have conducted a variety of cold start tests with our newest hybrid (scheduled for emissions testing in January 2016). Here are some recent results (arranged in order of duration, shortest to longest):

Since the test data likely won’t mean anything to most people, we suggest watching the video(s) at the bottom. They are very short (about 3 minutes each) and cover the very beginning of a cold start.

Basically, we take about 9-10 pounds of relatively small split wood, and stack it crosswise on the bottom of the firebox. We put a couple pieces on the bottom that go front to back, to improve airflow around the load. On top of the split pieces, we put a small stack of kindling (consisting of three or four 6” pieces of 1” x 4” dimension lumber) with paper in the middle. We have experimented with stacking this little pile as a “college bonfire” and as a “tee-pee” and as an “octagon”.

Next, we light this little stack of kindling, which is able to ignite both our secondary combustion and catalytic combustor in the first 3 minutes, as the video shows. The kindling burns and coals from the kindling fall down into the split pieces, which are subsequently ignited and burn merrily for about an hour (on high, with all the air controls wide open), producing a nice coalbed and very low emissions.

We’ll post more results in a few days.