03 Dec

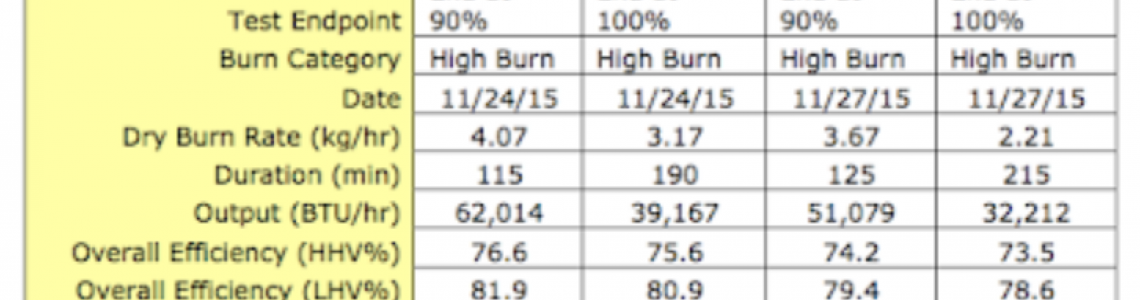

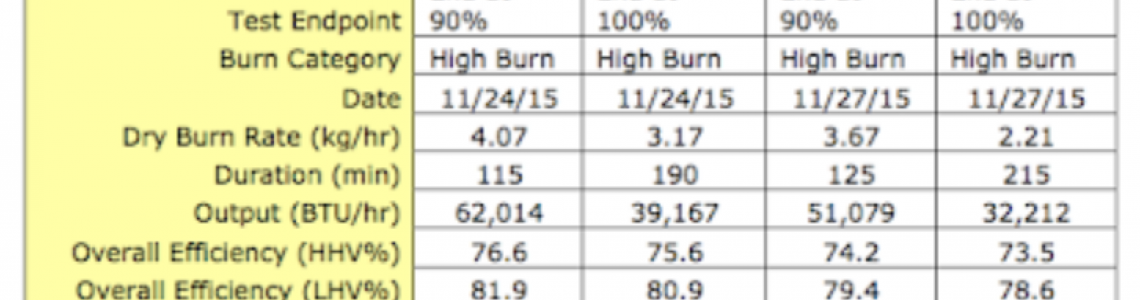

Below is data from 2 Cordwood High Burns (which followed the Cordwood Cold Starts on 11/24 and 11/27 – see previous posts). These are R & D Tests.

Each load was about 25 lbs. (in a 2.5 cu. ft. firebox). The fuel was all Hard Maple with average moisture content of 22%.

The 11/24 High Burn started when the Cold Start reached 15% of the test load (3.4#). The 11/27 High burn started when at just under 10% of the test load (2.4#).

The 11/24 load was packed tight (very little air space, and a relatively solid mass). The 11/27 load had smaller pieces on the bottom, bigger pieces on the top, and a little more air between the pieces.

We are deliberately altering the start conditions and loading procedures to try to determine the range of possible outcomes for a High Burn using cordwood in this new stove.

We indicate two results for each test: first where the test fuel load has reached 90% consumption, and second when it has reached 100% consumption.

In other words, for the 11/24 test, the first set of results is when approximately 22.5# of a 25# load has been consumed, leaving a coalbed of 5.9# (3.4 start + 25# load less 22.5# burned = 5.9#). The second set of results for the 11/24 test is when the test load has been completely consumed (and the remaining coalbed is 3.4#, the same as when the fuel was loaded. Note the difference in output and emissions in each pair.

|

Why report the test both ways? EPA has traditionally reported all test results when the test reaches 100% completion. The industry wants to report results for new cordwood tests when the test reaches 90% completion.

Even High Burns can have long “tails” as you can see. The last 10% of High Burn fuel can take as long as 90 minutes to burn. As you can also see, the results are very different depending on how you define the test – start and end definitions, loading protocol, and fuel.

More on high burns and suggested industry protocols will follow shortly.